Our offer

of vibration tests

Sopemea is recognised for its expertise in vibration testing, with support for clients both upstream (programme, procedure) and downstream (analysis of results).

Sopemea offers several types of vibration tests. We have electrodynamic exciters (or vibration pots), electrohydraulic vibration tables, shock machines and various sensors such as accelerometers. These test facilities enable us to qualify your equipment by means of resonance frequency research (RDF), sine vibrations, random vibrations or shocks.

Our in-house design office enables us to offer you turnkey, tailor-made solutions. Whatever your sector of activity, Sopemea is able to carry out a vibration test programme that will fully meet your qualification objectives. We have particular experience in the industrial, aeronautical, nuclear, rail, automotive, military, naval and capital goods sectors. Our technicians and engineers are experts in vibration testing and can adapt to all types of equipment.

We cater to all sectors, with a particular focus on defence, transport, energy and industry.

Sopemea can thus carry out various high or low frequency vibration tests (0.1 to 5000 Hz) with a large capacity for recording and processing measurement channels:

- Seismic tests: response spectrum, beats

- Sine vibration tests: resonance frequency search (RDF), fatigue, windmilling...

- Random vibration tests: power spectral density (PSD), endurance

- Shock tests: half-sine, sawtooth end-point (DSPF), shock response spectrum (landing-catapulting)

- Mixed tests: sine + noise, noise on noise, gunshot...

- Combined tests: vibration + temperature

Low frequency

vibration tests

These types of tests are carried out using vibration tables. Sopemea has some of the most powerful vibration equipment in Europe:

- A 3m x 3m biaxial table, equipped with two 300 kN electro-hydraulic jacks, performs earthquake tests on large equipment weighing several tonnes. The Vélizy laboratory is equipped with two 10-tonne overhead cranes and several access points within the halls for transporting your large equipment.

- A 2m x 2m triaxial table, supporting up to 2 tonnes. This testing facility benefits from a dedicated team of experts to carry out your earthquake tests and multi-axis vibration tests. => See article

All types of vibration environments can be created at Sopemea, regardless of the sector of activity: nuclear, aeronautics, transport, defence, aerospace, telecoms, naval, etc.

Our low-frequency vibration tests comply with the following standards, among others:

- Electrotechnical standards: IEC 60068—XX...

- Railway standards: IEC 61373, EN 50155, etc.

- Nuclear standards: RCCE, CRT 91C112, IEC-IEEE 680-344, STD7426, etc.

- Aeronautical standards: ABD100 (Airbus), DO160, etc.

High frequency

vibration tests

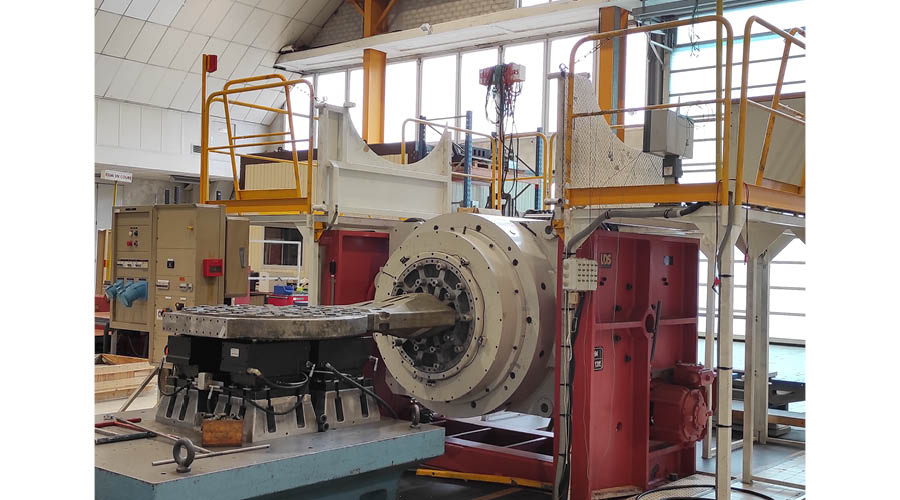

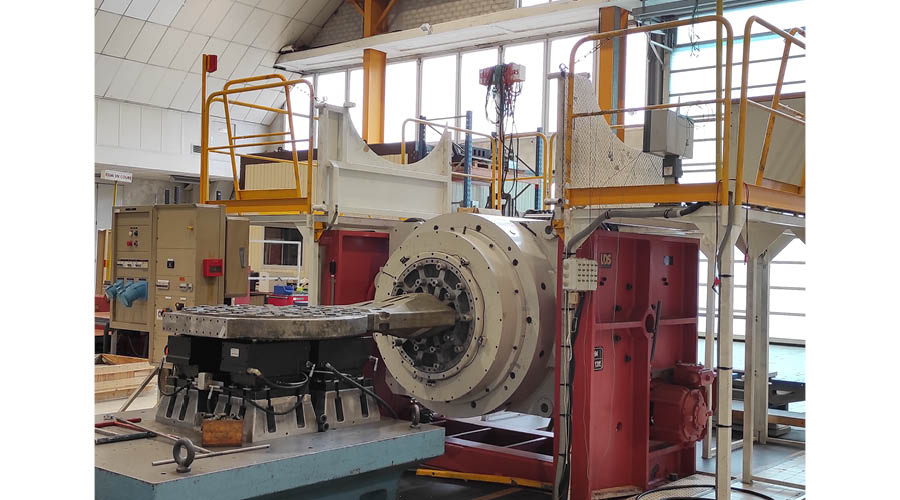

These types of tests are performed by electrodynamic exciters. The diversity of means covers a very wide range of equipment. Sopemea has the largest electrodynamic vibrator in Europe, with a force of 300 kN. Two overhead cranes of 10 tonnes each, a 9-tonne forklift truck, and a laboratory opening of 7m x 6m make it possible to handle bulky materials.

Our high-frequency vibration tests include sine, random and shock tests.

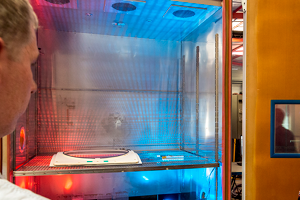

Climatic chambers or hot and cold generators positioned on the electrodynamic exciters allow combined vibration and temperature tests to be carried out on equipment sensitive to the climatic environment, for example in the automotive or aeronautical industries.

Our high-frequency vibration tests meet the following standards, among others:

- Electrotechnical standards: IEC 60068-2-XX...

- Aeronautical standards: DO-160, MIL STD 810...

- Military standards: STANAG 4370, DEF-STAN 0035...

Our experts answer your questions

about vibration testing

-

How are vibrations measured on equipment?

Vibrations are mainly measured using specific sensors, the most common being accelerometers. Accelerometers convert acceleration (g) into an electrical signal. This signal is then recorded and processed to obtain vibration parameters. A velocimeter (or speed sensor) can also measure vibration speed. The displacement sensor is used to measure the relative displacement between two points.

The sensor signal is analysed by a data acquisition system (DAQ) and spectrum analysis software (fast Fourier transform or FFT) to identify resonance frequencies, amplitude and other vibration characteristics. Common units of measurement are:

- acceleration (m/s² or g)

- velocity (mm/s or inch/s)

- displacement (mm or inch)

-

What are the five modes of vibration?

In engineering and modal analysis, the vibration of a structure is often broken down into natural modes of vibration, characterised by a natural frequency and a specific modal shape. Although there is no universal classification of the ‘5 modes’, here are five fundamental concepts or types used to describe vibratory motion:

- Free (or natural) vibration: movement that occurs after initial excitation, without any continuous external force (determines natural frequencies).

- Forced vibration: movement maintained by a continuous external force or excitation (e.g., motor imbalance).

- Damped vibration: vibration whose amplitude decreases over time due to energy dissipation (friction, air resistance).

- Undamped vibration: theoretical model where energy is not dissipated and the amplitude remains constant.

- Resonance: critical case of forced vibration where the excitation frequency is equal to or very close to a natural frequency of the structure, leading to a potentially destructive amplification of the amplitude.

-

What is the purpose of vibration testing?

Vibration testing is essential in many fields (aerospace, automotive, electronics, etc.) and serves several crucial purposes:

- Design and robustness validation to ensure that the product or structure can withstand the dynamic stresses it will encounter in its real environment (transport, machine operation, earthquake, etc.) without structural or functional failure.

- Identifying resonance frequencies in order to determine the critical frequencies of the system. Knowing these frequencies allows the design to be modified so that they do not coincide with the operating frequencies.

- Product qualification is used to demonstrate that it complies with the industrial, military or environmental standards specified for its category (qualification or accelerated ageing tests).

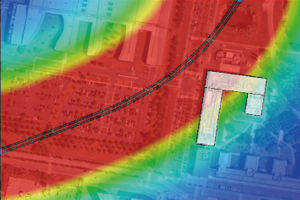

- Diagnostics and predictive maintenance (on rotating machines) measure vibrations during operation in order to detect mechanical faults (misalignment, imbalance, bearing failure, excessive play) before they cause catastrophic failure.

Why

choose Sopemea?

A complete range of tests and related services

+ Over 75 years' experience in qualification testing

A local network

Discover our

news