Ensure the performance of your equipment

when subjected to mechanical stresses

The strength and longevity of your industrial equipment can be compromised by external stresses such as ageing, impacts or inertial forces. In sectors where performance is a key criterion, it is essential to verify mechanical strength. Sopemea, a subsidiary of the Apave Group, is your trusted partner for reliable, COFRAC-accredited mechanical testing.

When it comes to mechanical testing, recognised technical expertise and state-of-the-art equipment are key. Your challenge: to turn mechanical risk into an opportunity to verify and test the strength and reliability of your industrial equipment.

Our expertise, backed by that of the Apave Group, guarantees you:

- The best testing resources on the market

- Support for your studies and simulations

- The development of your teams' skills

Adressing your

mechanical challenges

We assisted ALSTOM in qualifying train sets designed to run on the Lyon metro. Our client wanted to ensure the structural integrity and reliability of the carriages before they entered service by subjecting them to extreme vertical loads that replicated the maximum stresses they might encounter.

Conducting these mechanical tests was a major challenge for ALSTOM: ensuring the trains' resistance to permanent and exceptional stresses in order to meet the specifications of the railway sector.

- Test preparation

Test preparation

- Testing

Testing

- After testing :

After testing :

- Test preparation

Test preparation

- Testing

Testing

- After testing :

After testing :

- Test preparation

Test preparation

- Testing

Testing

- After testing :

After testing :

Our mechanical tests meet

your sector-specific requirements

Mechanical testing is a major challenge and a regulatory requirement in all areas where strength and performance are non-negotiable. We support you with a rigorous methodological approach, based on our expertise, to meet the most stringent specifications in your sectors. As a guarantee of quality and reliability, our tests are COFRAC accredited.

Mechanical testing in the aerospace sector :

- Your need: to validate the structural integrity and reliability of your equipment, particularly in terms of static loads and flight-induced fatigue.

- Our solution: fatigue and fracture analysis tests with real-time monitoring under constant acceleration (using a centrifuge).

- Examples of standards covered: RTCA DO-160, MIL-STD

- Your benefit: reduced risk of in-flight failure thanks to rigorous validation of the design under extreme loads.

Mechanical testing in the railway sector:

- Your need: to ensure the strength and durability of your railway equipment components when subjected to the repeated static and dynamic loads inherent in rolling stock.

- Our solution: fatigue testing to simulate operational life and static and dynamic testing.

- Standards covered: IEC 61373, EN 50155

- Your benefit: compliance with standards, reduction in unexpected maintenance costs and extended equipment service life.

Mechanical testing in the defence sector

- Your need: to confirm the functionality of your weapon systems, land or naval equipment when subjected to inertial loads and unexpected mechanical stresses in the field.

- Our solution: shock testing, static testing and acceleration simulation for components subjected to intense manoeuvres.

- Standards covered: MIL-STD-810 and STANAG

- Your benefit: guaranteed operational reliability and system safety, ensuring compliance with the most stringent military and defence requirements.

Our testing facilities ensure

the durability of your equipment

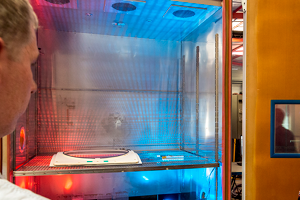

Sopemea has all the necessary equipment in its 25,000 m² laboratories in France and the United Kingdom for your mechanical testing campaigns. By choosing Sopemea, you are relying on one of the European laboratories with the most extensive mechanical testing facilities. Our expertise is based on state-of-the-art equipment, guaranteeing the accuracy and reliability of your qualification campaigns.

Static characterisation and material durability

These tests, which are fundamental for evaluating the design and service life of your equipment through tensile, compression and bending tests, are made possible by static and dynamic machines. They enable the precise measurement of tensile and compressive forces, thereby determining resistance thresholds. In particular, we use tensile testing machines with a capacity of up to 25 tonnes.

Resistance of your equipment

To analyse the response of your structures to dynamic environments such as vibrations, shocks, falls and fatigue, we have various testing methods at our disposal:

- Electrodynamic (300 kN) and electrohydraulic exciters capable of generating sinusoidal or random vibrations ranging from 0.1 Hz to 3000 Hz. These testing methods generate the fatigue profiles and complex vibrations required to qualify and analyse the resistance of your equipment.

- Impact machines that reproduce impacts and shocks, ensuring the validation of your structures' resilience. This equipment can apply a force profile of up to 2,500 g / 10 ms to your equipment.

Constant acceleration simulation

We have two centrifuges for qualifying your components subjected to intense inertial forces. They apply constant acceleration forces (up to 80 g) to equipment weighing up to 40 kg, enabling your equipment to be qualified. We also offer real-time monitoring to confirm that there is no functional or structural damage to your equipment during the application of stress.

Customised test benches

Our in-house design office can customise the equipment needed to operate your equipment during testing. Whether your equipment needs to be immersed, pressurised or maintained at a certain temperature, our technicians can build a unique, tailor-made test bench. Finally, data acquisition systems are available in our mechanical testing laboratories to record several hundred measurement channels of all types of quantities (accelerations with or without contact, displacements, stresses, forces) as well as recorders for functional control of equipment (dry contacts, micro-cuts, electrical rebounds).

Enhance your skills with

our mechanical testing training courses

Invest in your teams' expertise to gain autonomy, better interpret results and optimise the monitoring of your testing campaigns. Sopemea offers 2- to 3-day training courses covering the fundamentals of mechanical testing.

Our experts answer your questions

about mechanical testing

-

What is the purpose of mechanical testing?

The main purpose of mechanical testing is to evaluate the behaviour and strength of equipment or materials by applying mechanical stresses that simulate real-life conditions of use. This ensures their performance and suitability before they are placed on the market. -

What is a compression test?

A compression test is a type of test that involves subjecting a sample to a force that tends to shorten or deform it. This test is performed to measure the material's resistance to crushing. -

What is an impact test?

An impact test is a mechanical test that is part of vibration testing. It involves applying a sudden and violent stress to equipment to simulate events such as impacts or falls in order to verify the integrity of the material. -

What is an endurance test?

An endurance test is a type of dynamic structural test that aims to determine the lifespan and behaviour of equipment when subjected to stress cycles. It assesses the product's ability to withstand stress over time, often in the context of accelerated ageing. -

What is a fatigue test?

A fatigue test is a dynamic test that subjects equipment to repeated, cyclical stresses to assess its resistance to recurring stresses and its long-term durability.

Why

choose Sopemea?

A complete range of tests and related services

+ Over 75 years' experience in qualification testing

A local network

Discover our

news