Ground

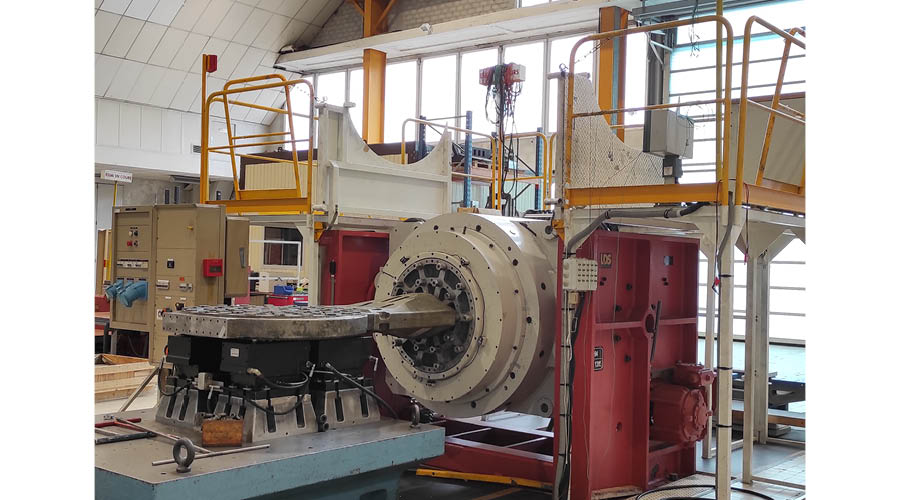

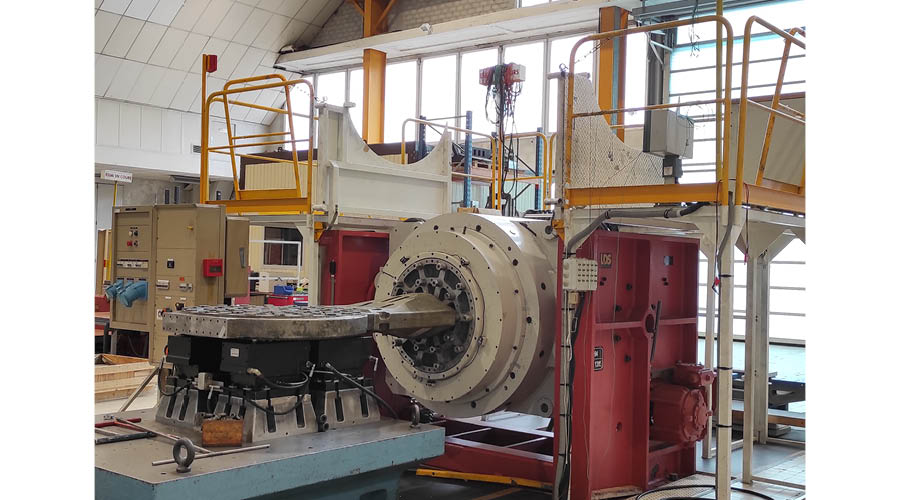

vibration test

All new aircraft models must be certified by a Certification Authority (in Europe this is the EASA), before they can be authorised to enter service. And to be certified, the first aircraft must undergo all kinds of tests. These include the Ground Vibration Test (GVT). This is a specific service that Sopemea, a subsidiary of the Apave Group, has been providing to Dassault Aviation since the 1960s.

Atlantic, Jaguar, Mirage, Rafale, Falcon... all types of aircraft, civil and military, have undergone a GVT before being marketed. "The relationship between the two companies is a historic one. The latest member of the Falcon family, the F6X, was subjected to this test for a fortnight in 2020 in partnership with ONERA, says Bernard Colomies, Technical Director at Sopemea.

2 questions to ....

Catherine Michelin

Managing Director of Sopemea

What does the aerospace sector mean to Sopemea?

It's part of our DNA. It represents the letter "A" in our acronym: Sopemea stands for Société pour le Perfectionnement des Matériels et Equipements Aérospatiaux. Aerospace was our first historic market and currently accounts for a third of our business. Our customers are equipment manufacturers, systems integrators and aircraft manufacturers. We offer them a range of services to support them throughout the chain, from the design of a system to its certification, before it is put on the market. This takes the form of studies, writing qualification procedures and simulating flight conditions.

"Digital testing and simulation to support players in the aeronautics industry"

What are Sopemea's specialities?

As the Apave Group's qualification division, we offer a full range of testing services, involving the testing of all types of materials, systems and equipment to assess their durability in constrained environments: vibratory, thermal and climatic, and electromagnetic. For example, we carry out numerical and physical lightning simulations, vibration tests to validate materials, and maintenance operations on the test equipment itself. We have acquired this expertise thanks to our aerospace customers. As a result, we are now able to offer a broader range of services to industrial customers facing the same type of constraints, such as the nuclear and defence sectors, and more broadly all types of industrial products and equipment.

Our latest

News