Testing, measuring, and qualifying:

key skills strengthened in Toulouse

Sopemea, a subsidiary of the Apave Group, is expanding its testing services in Toulouse with the acquisition of Continental Automotive France's Qualification Laboratory. With this acquisition, Sopemea is strengthening its expertise at several levels in the following areas:

- EMC: radiated and conducted immunity, ESD electrical testing...

- Climatic, corrosion, tightness, vibration, mechanical and accelerated testing..

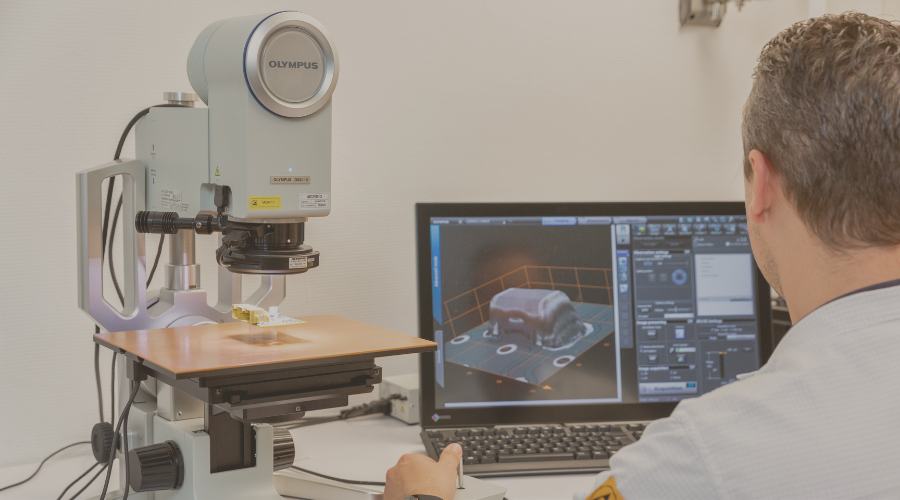

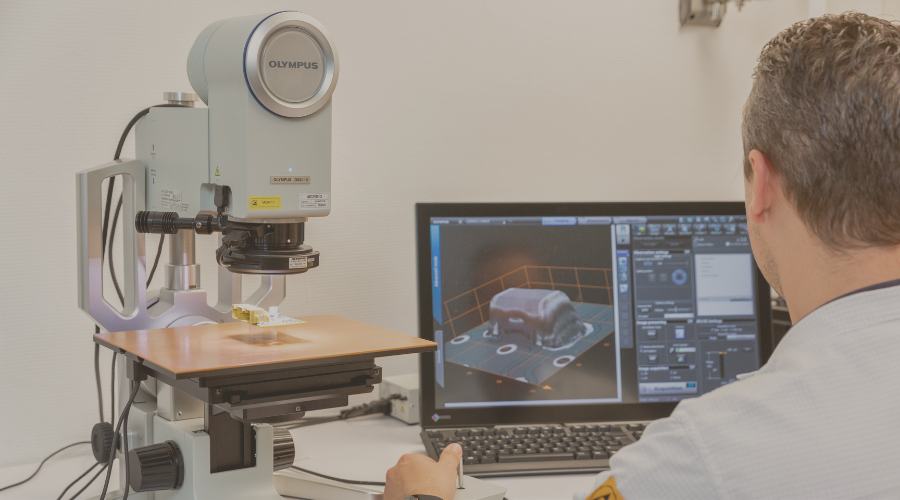

- Failure and material analysis (destructive and non-destructive): control of electronic boards, cross-sections, dimensional measurements, 2D/3D X-rays, electronic microscopy, technical cleanliness...

Following this acquisition, the Continental Automotive France Qualification Laboratory becomes Sopemea Testing Laboratory Services (TLS).

Focus on this

qualification laboratory

Failure and

Materials Analysis

Advanced techniques such as 2D/3D X-ray imaging (for non-destructive internal visualisation), electron microscopy (for nanometric analysis) and technical cleanliness analysis (contaminant detection) are also used. These analyses are fundamental to continuous product improvement, production problem solving and the qualification of new materials.

Environmental

mechanical and climatic tests

More general mechanical tests are also carried out, as well as accelerated tests (HALT) to predict the service life of components under extreme conditions. The aim is to guarantee the robustness and reliability of equipment, particularly for demanding sectors such as the automotive, aerospace and defence industries.

Expertise in

electromagnetic compatibility (EMC)

Electrical ESD (electrostatic discharge) tests are also carried out, simulating the static electricity discharges that components may be subjected to. These tests are essential for the safety and proper functioning of electronic systems, particularly in connected vehicles and critical applications.

I am absolutely delighted to welcome Continental's qualification laboratory to Sopemea. This acquisition, which brings together our complementary expertise, is a major strategic step for our development. In particular, it adds a new skill set in the form of materials analysis. Our shared approach to our businesses will enable us to strengthen our position as a trusted third party in the market. I am particularly pleased with this development, which ensures a promising future for the teams involved and guarantees continuity of high-quality service for all our customers.

Find

Our News